WET PAN MILL

WET PAN MILL

WET PAN MILL

Startpage > Products > Mechanical and plant engineering > Coarse ceramics > Crushing > Wet pan mill

Our product range in the area of wet pan mill

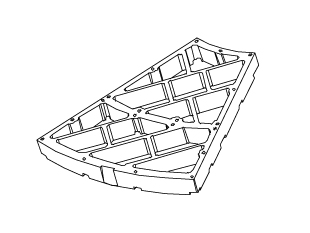

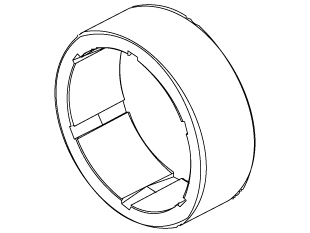

The pan mill (DKW) is one of the most effective preparation machines for plastic ceramic bodies. Combined with the high weight of edge rolls, different relative movements under the edge rolls and due to the slow operating mode the body is effectively crushed, sheared and mixed. Moreover water can be added and the body can be plasticized further.

Energy expenditure is relatively low and even the specific wear parts costs Euro/t are very low.

Description

Diameter of edge roll x width

Edge rolls

Diameter of crushing bed

Weight of

edge roll

Nominal torque

Nominal capacity

Capacity (12×40)

Unit

mm

Piece

mm

t

1/min

kW

t/h

DKW 1860

1.800×600

2

4.400

10,6/10,1

8-12

55

25-55

DKW 1870

1.800×700

2

4.400

13/12,6

8-12

75

40-70

DKW 2070

2.000×700

2

4.400

15/13,5

8-12

90

50-70

DKW 2080

2.000×800

2

5.100

17,4/16,5

8-12

110

60-90

DKW 2180

2.100×800

2

5.800

22/22,1

8-12

200

80-120

DKW 2080-4L

2.000×800

4

5.800

16,1

8-12

200

90-160

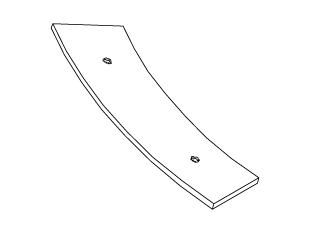

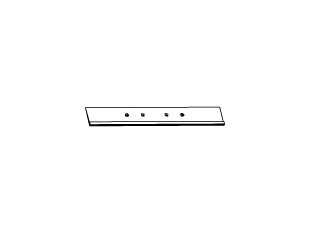

Spare parts

Application

- Strucural ceramics

- Fine ceramics

YOUR CONTACT PARTNER FOR CERAMIC

Variables

JavaScript

PDF enquiry form

You will help us to process your request quickly if you fill in our pdf-forms with as detailed information as possible and send it to us by FAX to +49(0)9835524 or by e-mail to anfrage@rehart.de.